carbon fiber material, this has been detained in the automotive industry ldquo pyramid; rdquo ;, high-end species seems about to break free —- Many manufacturers are carbon fiber capable of high-volume applications and work with, the BMW i series BMW is the product models reflect the results of the efforts in this regard.

Introduction:

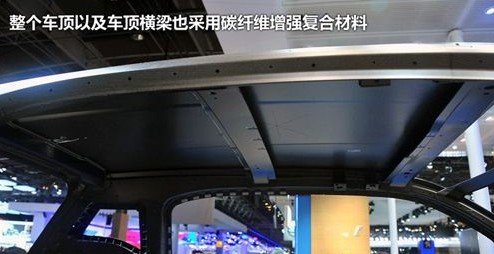

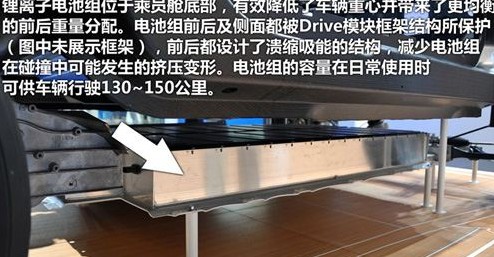

BMW i series models using ldquo; LifeDriverdquo; modular architecture, consisting ldquo; Liferdquo; and ldquo ; Driverdquo; two separate modules, ldquo; Liferdquo; Representative portion of the passenger compartment, the carbon fiber composite material of CFRP ultra-lightweight and high-strength structure, and ldquo; Driverdquo; then the suspension, battery, drive systems and collision protective structure into the overall module. A closer look reveals that, in fact, the concept of this structure is similar to a conventional non-bearing body, but high-strength carbon fiber composite passenger compartment of the vehicle body are those of a conventional non-bearing compartment unmatched.

quot; Lifequot; module – carbon fiber composite material of the passenger compartment: [ 123]

quot; Drivequot; module – multiple roles:

Summary:

BMW i series of electric vehicles are the two most important highlights, one is modular manufacturing concept LifeDrive architecture, the passenger compartment and split chassis parts, fight like a simple building blocks, which will for the future modification of the vehicle, repairs, extensions and so bring about a revolution; second major highlight is the all-carbon-fiber body, which marks the carbon fiber material will be able to meet the mass productionClaim.

past carbon fiber composite material subject to the process and cost, not large-scale popularization and application, but now it seems that this is no longer a problem, on the one hand, suppliers have developed a lower cost but comparable strength carbon fiber material with new material, on the other hand, new processes and formulations also reduce the cost of the carbon fiber composite materials, production efficiency. It is said that BMW and SGL Group to develop carbon fiber composite material and the production process will be half the cost, and easier to mass production, Volkswagen, Mercedes-Benz, PSA and other groups have also joined the camp of carbon fiber material developed by them. It can be predicted, instead of carbon fiber composite material and of a similar nature are expected in the next 5 to 10 years, stepped down to become the mainstream passenger car materials, all the people ldquo; lightweight rdquo; era is not far away.