1 Glossary

power steering, by definition, to resist force by increasing the steering resistance, so that the driver requires less force will be able to complete the turn, also known as power steering, English as powersteering, It was originally intended to allow some of the heavier weight can more easily operate large vehicles, but now has been very popular, which makes driving easier and easier, and make the vehicle more agile response to improved security to some extent.

The most common mechanical power steering hydraulic power, hydraulic power electronics, electric power three.

2, the mechanical hydraulic power

mechanical hydraulic power is the most common kind of power the way it was born in 1902, invented by the British FrederickW.Lanchester, and the first commercial application then postponed until after half a century, the 1951 Chrysler sophisticated hydraulic steering system used in the Imperial on cars. Since the technology is mature, reliable, and low cost, it is widely popular.

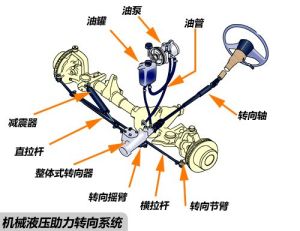

Mechanical hydraulic power

Mechanical hydraulic power

The main composition

The main mechanical components of hydraulic power system has a hydraulic pump, tubing, a pressure fluid control valve, V-belt drive, storage tanks and so on. This embodiment is part of the engine power output is converted into hydraulic power pressure, a force is applied to the steering assist system, thereby steering the tire wheel.

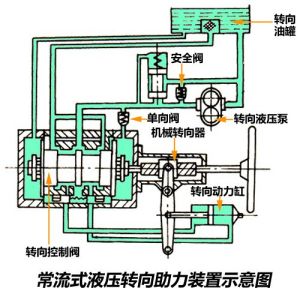

can be divided into hydraulic pressure and a constant flow hydraulic power booster according to the different embodiment of the flow system.

hydraulic pressure booster

Characteristics of hydraulic pressure power steering system is in a neutral position or whether the steering position, the steering wheel is held stationary or in rotation, the fluid in the conduit system always maintained a high pressure state.

pressure-type constant flow hydraulic power

pressure-type constant flow hydraulic power

and the constant flow hydraulic power steering pump, although a steering system is always working, but hydraulic power system is not working, pump in an idle state , line loadSmall than atmospheric pressure, and now most of the hydraulic power steering systems use the constant flow. It can be seen Either way, the steering pump are essential components, which can be input mechanical energy into the engine oil pressure is.

A constant flow

A constant flow

3, a mechanical hydraulic power disadvantages

between the

Mechanical hydraulic power steering of the steering wheel all the mechanical components are connected, precise control, direct road feel, feedback rich; a hydraulic pump driven by the engine, steering with plenty of power, the size of the vehicle are applicable; mature technology, high reliability, low cost manufacturing average.

Since the oil pump is driven by engine power, energy consumption is relatively high, so the driving force of the vehicle is consumed virtually portion; piping structure of the hydraulic system is very complicated, the vast amount of various fluid control valves, late maintenance costs required; the entire oil keep high pressure, life will be affected, these are shortcomings where mechanical hydraulic power steering system.

4, the electronic hydraulic power

Due to the mechanical hydraulic power require significant power consumption of the engine, so people on the basis of improvement in the mechanical hydraulic power, development of a more energy-saving electronic hydraulic booster steering system. The system of the steering pump is no longer directly driven by the engine, but rather is driven by an electric motor, and the installation of the electronic control system on the basis of the previous, such that the magnitude of the steering assist force is not only related to the steering angle, is also associated with the vehicle speed. Increasing the hydraulic reaction apparatus and liquid dispensing valve on a mechanical structure, the new electronic control system includes a vehicle speed sensor, solenoid valve, the steering ECU and the like.

Electronic hydraulic power

Electronic hydraulic power

Electronic hydraulic power machine has most of the advantages of the hydraulic booster, while reducing energy consumption, the reaction is also more sensitive, but also according to the size of the steering angle, vehicle speed and other parameters to adjust itself more humane. But the introduction of many electronic unit manufacture, maintenance costs will increase accordinglyPlus, the use of mechanical stability is not as reliable hydraulic type, as the technology continues to mature, these shortcomings are being gradually overcome, electronic hydraulic power has become a lot of home models to choose from.

5, the electric power

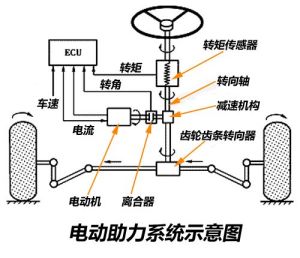

is the abbreviation of the English ElectricPowerSteering the EPS, i.e., electric power steering system. Electric power steering system is the development direction of the automobile steering system. The system provided by the electric power steering unit directly, eliminating the need for hydraulic power steering systems necessary power steering pump, hoses, hydraulic fluid, and a belt pulley mounted on the engine, saving energy and protecting the environment. Further, with a simple adjustment, and assembly can provide flexible steering characteristics under various conditions. It is precisely because of these advantages, electric power steering system as a new steering technology, the challenge we are very well-known, already has 50 years of history of the hydraulic steering system.

When the driver performs steering in the steering wheel, the steering wheel base of the steering wheel detected by the sensor and the magnitude of the torque, the voltage signal is conveyed to the electronic control unit, the electronic control unit detects the rotation torque sensor from the voltage signal, a rotational direction and a vehicle speed signal, etc., sent commands to the motor controller, the motor output corresponding to the magnitude and direction of steering torque, thereby generating auxiliary power. When the vehicle is not turning, the electronic control unit does not issue an instruction to the motor controller, the motor does not operate.

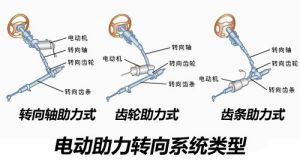

The electric power

The electric power

power steering system type technological superiority

power steering system type technological superiority

, energy saving due to the engine running, the pump is always active hydraulic steering system so that the whole engine fuel consumption increased by 3% to 5%, while the EPS battery as energy to the motor-driven element, can work independently of the engine, the engine directly EPS consumes little fuel. EPS there is no fuel leak hydraulic power steering system, EPS through electronic control, almost no pollution to the environment, but also reduces fuel consumption.

2, to facilitate mounting the main components of the EPS can be equipped with integrated, easy to arrange, as compared with the hydraulic power steering system reducing the number of components, the hydraulic system does not require pumps, tubing, pressure and flow control valves, storage tanks etc., a small number of components, easy assembly, saving time.

3, high efficiency hydraulic power steering system efficiency is usually 60 to 70 percentage percentage, and the higher the efficiency of the EPS, up to 90%.

4, good road feel conventional hydraulic power steering pure mostly fixed magnification, a large driving force is working, but can not achieve a sense of easiness and road car while driving at various vehicle speeds. The hysteresis characteristics of the EPS system can be compensated for by EPS controller software, making the car at all speeds can be satisfied with power steering.

5, aligning good EPS system is simple, operation is not only simple, but also can be adjusted EPS controller software, the best return-resistance, thereby improving vehicle handling stability and comfort

Main structure

the electric power steering system by the steering sensor device, the vehicle speed sensor, a mechanical assist means to provide steering assist motor and a microcomputer control unit.

works

The microcomputer control unit and the steering sensing arrangement outgoing vehicle speed sensor to determine the magnitude and direction of steering, and the steering assist operation of the drive motor.