1. Introduction

located between the engine and the flywheel housing gearbox, the clutch assembly is fixed with screws on the rear plane of the flywheel, the clutch output shaft is the input shaft of the gearbox. In the vehicle is in motion, the driver may need to depress or release the clutch pedal, the engine and gearbox is gradually engaged and temporary separation, or to cut off the input power of the engine is transmitted to the transmission.

the driving shaft and able to engage or disengage the driven shaft work required at any time by mechanical parts. It can be used to operate the machine drive train starting, stopping, and reversing the transmission and the like. Clutch wide range, according to the nature of the work can be divided into: ①-operated clutch. Mechanical manipulation method thereof, electromagnetic, pneumatic, hydraulic and the like, such as a clutch fitted (by the teeth, the teeth fitting or key transmission torque), a friction clutch (torque transmitted by a frictional force), the flexible air clutch (with compressed air to operate the clutch dilations tire friction member engaged or disengaged), the electromagnetic slip clutch (magnetic force is generated by an exciting current to transfer torque), powder clutch (magnetic powder magnetized by the exciting coil, the magnetic powder is formed chain to transmit torque). ② automatic clutch. Automatically by simple mechanical means or separate joining operation, is divided into safety clutch (transfer shaft can be automatically isolated when the torque reaches a certain value, thus preventing overloading, to avoid machine damage vital parts), a centrifugal clutch (when the drive shaft when the rotational speed reaches a certain value, due to the centrifugal force to make their own self-coupled or can be isolated after more than a certain speed) between the transmission shaft, the orientation of the clutch (overrunning clutch known by ratchet – engaging pawl or roller, wedge wedging action or movement way transmission torque, when the driving speed is lower than the driven shaft or the reverse shaft, the clutch is automatically separated).

2, the definition of

clutch, Hong Kong, commonly known as highly son, this is from the English Clutch comes, Taiwanese are often from Aberdeen or Japanese Kuraray ッ chi call it, is the car engine power or other mechanical power transmission means so as to switch to the axle.

a clutch installed between the engine and the transmission, a vehicle power train with direct hairMotivation associated assembly parts. Generally installed with the engine crankshaft and the flywheel clutch group, and cutting off the power transmission between the engine and the vehicle drive-train components. The whole process from the start to the normal car driving, the driver may be required to manipulate the clutch, the engine and drive train temporary separation or gradually engaged, or to cut off power from the engine to the driveline transmission output. Its role is to enable gradually engaged, thereby ensuring a smooth start between the car engine and the transmission; temporarily breaking the link between the engine and the transmission, and in order to reduce a shift shock when shifting; emergency braking when the vehicle can play separating action, to prevent overloading of the transmission and other drive train, and thus play a protective role. Clutch switch similar to, or engaging action of breaking away from the power transmission, the clutch mechanism and the driven portion of its active portion can be temporarily separated, and may be gradually engaged, and also it is possible to drive during the relative rotation. Non-rigid connection between the clutch driving part and the driven member. Any form of car has a clutch device, just different forms.

3 function

1 to ensure a smooth start car

[123 ] clutch function before starting the car is stationary, if the engine and gearbox are rigidly connected, once in gear, the car suddenly due to a sudden power downfield connected, not only mechanical damage, and the drive force is not enough to overcome the enormous inertial forces generated pediment car, the engine speed drops sharply and stalling. If the clutch when starting the engine and transmission is temporarily separated and then the clutch is gradually engaged, due to the presence of the phenomenon of slipping between the drive portion and the driven portion of the clutch, the clutch can be gradually increased by the outgoing torque of zero, the driving force of the car gradually increased, so that the car started smoothly. 2.

[123 ] clutch function before starting the car is stationary, if the engine and gearbox are rigidly connected, once in gear, the car suddenly due to a sudden power downfield connected, not only mechanical damage, and the drive force is not enough to overcome the enormous inertial forces generated pediment car, the engine speed drops sharply and stalling. If the clutch when starting the engine and transmission is temporarily separated and then the clutch is gradually engaged, due to the presence of the phenomenon of slipping between the drive portion and the driven portion of the clutch, the clutch can be gradually increased by the outgoing torque of zero, the driving force of the car gradually increased, so that the car started smoothly. 2.

to facilitate the shift vehicle is in motion, often for different transmission gear, to adapt to changing driving conditions. If no clutch is temporarily separated from the engine and gearbox, the force-transmitting gear engaged in the gearbox due to no loadThere are removed, which engages a lot of pressure between the tooth surfaces and difficult to separate. Another treatment will vary both the ring gear and difficult because of the peripheral speed of engagement. Even forced into engagement teeth also produce very end impact, easily damaged parts. The clutch and the gearbox of the engine is temporarily separated after a shift, a pair of gears engaged by the original load removed, the pressure between the mating surfaces is greatly reduced, it is easy to separate. And to be engaged with another gear, the drive gear due to the rotation inertia small to separate the engine, using a suitable gear shift operation can be engaged with the peripheral velocity equal or close to equal, so as to avoid or mitigate the impact of the gears.

3.

to prevent overloading the drive train when the vehicle emergency braking, wheel sudden sharp deceleration, and a drive train connected to the engine due to the rotation inertia, the rotation speed remains the original , which tend to produce much larger than the moment of inertia of the engine torque in the drive train, the drive train of the parts susceptible to damage. When the clutch is to transmit torque by frictional force, so when the driveline torque load exceeds the frictional force that can be transmitted, the master clutch, the slip will automatically driven portion, thereby preventing the drive train acts as overload .

4, the working principle

clutches The active portion of the clutch and the driven part by friction between the contact surfaces, with a liquid or as a transmission medium ( fluid coupling), or by a magnetic drive (electromagnetic clutch) to transmit torque, so that the separation may be temporarily, but also is gradually engaged, in turn, allows the drive during mutual rotation between the two parts.

clutches The active portion of the clutch and the driven part by friction between the contact surfaces, with a liquid or as a transmission medium ( fluid coupling), or by a magnetic drive (electromagnetic clutch) to transmit torque, so that the separation may be temporarily, but also is gradually engaged, in turn, allows the drive during mutual rotation between the two parts.

It is widely used in the automobile is spring-loaded friction clutch (referred to as a friction clutch).

issued by the engine torque by the friction of the flywheel and the pressure plate and the driven plate contact surface, transmitted to the driven plate. When the driver depresses the clutch pedal by passing parts of the diaphragm spring to drive the large end of the pressure plate move, when the driven part is separated from the active part.

5, operating essentials

three clutch operating essentials: a fast, slow two, three linkage. When lifting the clutch pedal, the operation will have to follow the principle of “a fast, slow two, three Interaction”. At the start, when the clutch pedal operation to neat, foot in the end, the complete separation of the clutch. By “a fast, slow two, three linkage” is the lifting of the clutch pedal during three phases, a fast start to lift, when the clutch pressure plate is gradually felt bound to semi-linkage, the pedal is lifted began to slow, in the semi-linked to a fully integrated process, the clutch pedal is slowly raised. While lifting the clutch pedal, the engine should be based on the size of the power, and then gradually step down the accelerator pedal, the automobile can be started smoothly. To smooth throttle operation appropriate only when the clutch is fully integrated in order to increase the throttle.

6, the principle of

for manual transmission vehicles, the clutch is an important component of the vehicle power system, which bears the power and cutting the connection between the engine work. In complex urban road or road driving, the clutch we became one of the most frequently components, and the use of the clutch is good or bad, directly reflects the level of the standard of driving, but also played a protective effect vehicle. Proper use of clutch, clutch master principle to use the clutch in exceptional circumstances to solve the problem, each driving a manual transmission car riders should grasp.

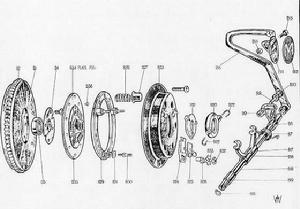

The so-called clutch, by definition means that the use of “off” and “bonded” to deliver the right amount of power. Clutch friction plate, spring plate, pressure plate and the power composition output shaft, which is located between the engine and the transmission, for transmitting the stored engine flywheel torque to the transmission to ensure that the vehicle is transmitted to at different driving conditions driving wheels amount of force and torque, belonging to the scope of powertrain. When the semi-linkage, the power input terminal and power output terminal of the clutch rotational speed difference is allowed, i.e. throughThrough which the rotational speed difference to achieve the right amount of power transmitted.

three clutch operating state, i.e. it does not depress the clutch interlocking, do not depress the clutch interlocking whole, and some clutch half interlocking. When the vehicle is started, the driver depresses the clutch, clutch pedal movement pulled back pressure plate, which is separated from the pressure plate and friction plate, the pressure plate and flywheel case completely in contact, there would be no relative friction. When the friction plate on the vehicle during normal driving, the pressure plate is firmly presses against the flywheel, at this time remains relatively static friction between the maximum friction force, an input shaft and the output shaft between the pressure plate and the friction plate, they are the same rotational speed . The last one is a semi-interlocking state of the clutch friction plate of the friction plate and the pressure less than full interlocking state. At this time, the friction between the pressure plate and the clutch plate on the flywheel sliding friction state, the flywheel speed is greater than the rotational speed of the output shaft, the transmission power is transmitted from the flywheel to the transmission portion. In this state, the equivalent of a soft connection state between the engine and drive wheels. After

In general, the clutch is starting to play a role in the vehicle and shifting time, when the presence of a rotational speed difference between two shafts and the shaft of the gearbox, the engine power must be cut to a shaft, the synchronizer good to the rotational speed of a shaft with two shaft synchronized. After the feed gear is engaged, and then through a clutch shaft coupled to engine power, so that power continues to be transmitted. In the clutch, there is an essential buffer means. It consists of two disk-like flywheel together in a rectangular groove on the disc playing, the spring is disposed within the recess, in the face of fierce impact, the elastic spring between the two discs each occurrence effect, buffering external stimuli, effective protection of the engine and the clutch.

In various parts of the clutch, the friction coefficient of the compression strength of the disk springs, friction plates, the diameter of the number of positions of the clutch, the friction plate and the clutch is a key factor in determining the performance of the clutch. The greater stiffness of the spring, the higher the friction coefficient of the friction plate, the larger the diameter of the clutch, the clutch better the performance.

7, tips

the clutch is to control the transmission and interruption of engine power. Use the clutch, it can also affect a car’s safety and life, how to master the clutchWith the skills it?

No matter not step on the clutch at the clutch during normal driving cars, is in a close contact state, the clutch should not slip. In addition to cars in the car start, low-speed brake and shifting need clutch pedal, the other right time not step on the clutch, or foot on the clutch pedal, the clutch pedal feet long on while driving, it is easy to causing slipping clutch, clutch ablation phenomena, serious or even clutch pressure plate, flywheel end surface ablation strain, leading to clutch failure annealing compression spring.

a slow speed two three linkage essentials starting operation of the clutch pedal is a fast, slow two, three linkage. I.e. faster lifting started when the pedal lift; semi-linkage occurs when the clutch pedal is lifted slightly slower; linkage to a fully integrated process, slowly lift the pedal. While lifting the clutch pedal, the engine according to the accelerator pedal of resistance gradually, so that a smooth start car. When fitting

in the shift driving the throttle, the manipulation of the clutch pedal to be depressed quickly and do not lift the semi-linkage phenomenon occurs, otherwise, would accelerate the wear of the clutch. Further, with attention to the accelerator operation. In order to shift smoothly to reduce the wear of the clutch and the transmission shift, the clutch shift method advocated the use of feet. Although this method is more complicated operation, but it is a good way to save car driving to save money.

less driving the clutch in an automobile, in addition to the low-speed clutch pedal needs parking brake, the brake in other cases so as not to depress the clutch pedal during braking. In a low-speed driving method of operating the parking brake to the brake pedal, clutch pedal and then, making the car to a halt smoothly.

8, fault diagnosis

If a manual vehicle, must be observed clutch, vehicle manual transmissions which clutch should be engaged smoothly separated completely under circumstances with, if there is a start is difficult, with when weak, weakness or climbing situation, you may hear some sound occurs between the transmission gear, there may be impact sound, or start shaking problem.

(1) abnormal sound clutch Phenomenon: emitted sound is not normal [automobile clutch 12 is engaged or3] Reason: lack of release bearing lubricants or bearing damage caused by dry friction; no gap between the release bearing and the inner end of the separation lever; separating dust and greasy oil between the bearing sleeve or the catheter serious release bearing and return the pedal return spring spring fatigue, broken off, so that the release bearing return poor; driven plate spline hole with its looseness spline shaft; a driven disc of the damper spring fatigue or fracture annealing; loose rivets driven disc friction plates or rivet loose or exposed rivet heads; pin holes and pin dual clutch transmission sheet intermediate pressure plate and the pressure plate wear open.

diagnosis and exclusion: slightly separated from the clutch pedal to make contact with the lever bearing and separating, if the “rustling” sound, compared with bearing abnormal sound, abnormal sound if still refueling described excessive bearing wear, damage rattling should replace; lift the clutch pedal depressed, if the impact sound occurs intermittently, separating the front and rear bearings are described traverse, replace the release bearing return spring; even pedal, if there is sound or freshly isolated clutch engagement just described follower loose rivets or exposed plate, the driven plate should be replaced.

(2) Automotive clutch is not complete

phenomenon: when the engine is idling, the clutch pedal, a gear in gear engaged crash and difficult, if barely hung, then the engine stall when the clutch pedal is not yet fully complete relaxation. Cause: the clutch pedal stroke is too large freedom; separation lever bending deformation, loose bearings, shaft support pin coming out, so that the height of the inner end of the release lever is difficult to adjust; separation lever to adjust properly, so the inner end or not in the same plane the inner end height is too low; dual-plate clutch intermediate pressure plate stopper improper adjustment screw, spring fatigue individual separation, break, or insufficient height, the intermediate pressure plate or on the drive pin does not move freely in the axial direction of the clutch driving the window; driven plate steel warping, cracking or loose rivets friction plate; new for the friction plate is too thick or reverse driven plate installed wrong; driven plate splined bore the transmission axis of the first spline shaft cassette; clutch hydraulic oil actuating mechanism , inadequate air or oil; a diaphragm spring force weakened; engine bearing wear or damage the engine crankshaft and the transmission input shaft coaxial.

diagnosis and rule out: Check automobile clutch pedal free travel, free travel if the adjustment is too large, the hydraulic actuating means for checking whether the fuel tank or reservoir insufficient air line and the necessary exclusion; check separation lever the inner end height, if the release lever is too low or not in the same plane, an adjustment is made,Otherwise, check driven disc installed backwards, then continue to check if no problem; check whether the disc warpage rivet driven off, the axial movement of the driven disk is if the cassette to be replaced or repaired.

9, the basic requirements

clutches  of the friction clutch should meet the following basic requirements: 1) to ensure that the maximum torque of the engine can be passed emitted, and there are some spare transmission torque.

of the friction clutch should meet the following basic requirements: 1) to ensure that the maximum torque of the engine can be passed emitted, and there are some spare transmission torque.

2)

when the separation can be done, complete separation, engaged soft, and has good heat dissipation capacity. 3)

moment of inertia of the driven portion as small as possible. Thus, in the separation of the clutch gear, a shaft portion connected to the rotational speed change of the transmission easier to input, thereby reducing the impact between the gears. 4)

have the ability to mitigate the impact of the rotational direction, the direction of vibration damping and noise. 5)

friction coefficient of the friction plate and pressure plate of the pressure change is small, stable operation. 6)

effort operation and easy maintenance. 10, a slip process

When the clutch slip occurs, correct the fault cause analysis. Cause

(1) causing the clutch slip

① excessive wear of the driven plate friction pad or exposed rivets;

② clutch pressure plate spring is too soft or broken;

③ free travel of the clutch pedal is too small;

there are on the driven plate friction plate ④ oil or aging hardening;

⑤ flywheel clutch engaged and loosening screws;

⑥ clutch master cylinder oil return hole clogging.

(2) Troubleshooting order and orientation

① check pedal play, do not meet the standard value, should be adjusted;

② If the normal free travel, should be removedThe clutch bottom cover, check the flywheel clutch cover engaging bolts are loose, if loose, should tighten;

③ clutch plate to see whether there is an edge oil thrown, if gasoline or oil should be removed with a base washed with water and dried, and then to identify and eliminate the source of the oil;

④ found severely worn friction film, exposed rivets, aging hardening, burning and the like is impregnated into the oil should be replaced new film, replacing new friction not have cracks or broken tablets, the depth of the rivet should comply;

⑤ checks clutch master cylinder oil return hole, such as clogging of the oil return hole should be clear;

⑥ If, after the inspection, repair adjustment, can not troubleshooting, decomposition of the clutch, the pressure of the spring check pucks. When good pressure plate spring, the length should be the same, such as uneven, new product should be replaced, as the spring force is slightly reduced, little difference in length, the spacer can be adjusted plus or minus the spring below.

11, is abnormal

1, note that the clutch is slipping, there are several reasons for such phenomena, mainly due to the free travel of the clutch pedal is too small, the release bearing is often pressed against the diaphragm spring the pressure plate is always in a semi-disconnected state. Or a clutch pressure plate spring is too soft or broken, loose screws in the clutch and flywheel.

2, in the engine idling state, when the clutch pedal is almost bottomed out, in order to cut off the clutch. Do not lift the clutch pedal, transmission gear was Guadang difficult or harsh crash occurs in gear or clutch pedal, the vehicle starts running, which show that the car’s clutch is not complete.

3, 3/4 when the clutch pedal, the clutch should be firmly bonded, or check whether the operation is appropriate, the pedal can be used in measuring ruler at the highest position to measure the height of the pedal, then measure the pedal depression the height of the resistance is felt, the difference between two values is the value of the vehicle clutch stroke.

4, if the abnormal sound occurs during the use of the clutch is not normal. Cause of the malfunction is badly worn release bearing, bearing return spring is too soft or broken, faulty diaphragm spring bracket and so on.

12, precautions slip handle Item

● stop participating in fat dry electromagnetic everything is used, otherwise the resulting torque reduction.

● necessary to clean the front magnetic means vergence cleaned to remove grease and rust debris.

.  ● vergence electromagnetic means may coaxially, it is possible for the shaft means axially fixed necessary, automatically with the driven some promise not have some axial movement, of the shaft means, the automatic concentricity between the shaft portion and the driven portion should be less than 0.lmm. ● When everything is working wet solenoid, it is necessary to add lubricating oil, a smooth approach to the choice of (1) lubricating oil pour points of conflict between the sheet; smooth (2) oil bath, which is immersed in the oil and everything about some 5 times the volume; and (3) the axis of the oil smooth, high speed selection of the axis of approach and supply high-frequency operation should be.

● vergence electromagnetic means may coaxially, it is possible for the shaft means axially fixed necessary, automatically with the driven some promise not have some axial movement, of the shaft means, the automatic concentricity between the shaft portion and the driven portion should be less than 0.lmm. ● When everything is working wet solenoid, it is necessary to add lubricating oil, a smooth approach to the choice of (1) lubricating oil pour points of conflict between the sheet; smooth (2) oil bath, which is immersed in the oil and everything about some 5 times the volume; and (3) the axis of the oil smooth, high speed selection of the axis of approach and supply high-frequency operation should be.

● When everything dog electromagnetic device, it is necessary to ensure that there is a certain gap between the end teeth, so that no wear tooth appearance when idling, but not larger than the value of δ.

● vergence is an electromagnetic brake and Class B insulation, the normal temperature 40 ℃. Operating temperature limit does not allow thermal equilibrium exceed 100 ℃, otherwise conflict with some coils easily damaged.

● power supply and control lines, power supply everything is usually 24 volts direct current (Special orders out). It consists of a single-phase or three-phase voltage by the step-down communication and a full-wave rectified, unregulated and filtering requirements, electrical power greater than the rated power of the electromagnetic vergence 1.5 times or more. Application of half-wave rectification power supply is necessary to install a freewheeling diode.