1, pressurized Category

This supercharger and turbocharger like, but it is not the engine the exhaust gas-driven, but driven by the engine with a belt. It turbo supercharger and the same principle, the intake air pressurized air by centrifugal force, to achieve the purpose of the compressed air.

substantially supercharger

substantially supercharger hood projecting from obvious, as the car Mustang as FIG. This supercharged air into the interior of the turbocharger, there are two helical blades compressed air, to the intake manifold after the inside. This can provide a powerful supercharged torque output. It is very popular in the accelerating race and street competitions.

Spiral supercharging

The spiral supercharger boost is derived basic model, but also looked like, but their compression intake was different. When air is drawn into the booster, spiral blade is forced into the intake manifold. This form is very effective for enhancing the supercharger rotation speed of each horse.

2, the mechanical supercharger

supercharger displacement pump is a positive displacement, referred to as a positive displacement pump. It is the same with the turbocharger, and may increase the density of the air pressure inside the intake pipe, to the pressure of the engine more air into the engine per cycle to burn more fuel, thereby increasing engine power per liter and average effective pressure, the power of the car, fuel economy and emissions are improved.

is a Roots blower supercharger essence, there are two rotors, each rotor are twisted a certain angle, for example 60 degrees to form a spiral. Two rotors driven by a belt by the crankshaft of the engine, the exhaust system with irrelevant. There is a fixed gear ratio between the crankshaft with a supercharger. The two counter-rotating rotors each have a plurality of protruding teeth intermesh at work. Twisted imports and exports with a specially designed rotor geometryCombination, help reduce pressure fluctuations, the air flow smooth, low noise during operation. This design also makes higher efficiency than conventional Roots blower. This supercharger rotors with helical and axial inlet may be up to speed 14,000r / min, thereby reducing the volume. It can be directly connected to the intake pipe by bolting outlet flange up use. Supercharger through its displaced volume and to match with the belt drive than the engine, while providing an excess of air flow at any engine speed.

supercharger installed in an engine

supercharger installation on a gasoline engine with a turbocharger as may be with an intercooler. This supercharger has a special design of the bypass valve, the degree of vacuum which is generated by the engine throttle. When the engine without the supercharger, the supercharger bypass valve will cause air circulation, in order to save energy. Base engine air intake system with integral mounting the supercharger. Because each engine installation has unique requirements, so most of the supercharger are designed for a particular engine.

3, supercharging principle

However, the seemingly perfect supercharger system, there is a small problem, because the power source of a mechanical supercharger driven entirely on engine, while the burden on the engine lighter, faster speed upgrade, this is the reason why the space race cars are dismantled in advance of air-conditioning compressor, if the equation (formula) racing, and even activate the motor, oil pump have changedTo an external connection, to reduce the burden on the engine caused, and therefore the turbocharger itself running resistance must be as small as possible, it will not drag on the efficiency of the engine.

However, the energy (boost value) generated proportional to the supercharger and the resistance, if the blind pursuit boost value, although the engine output power increase, the relative internal booster blades by wind resistance It will rise, when the resistance reaches a certain limit, the resistance of the supercharger itself will make engines under great burden, seriously affect the lifting of engine speed, so designers must achieve a compromise between the engine and boost the value of the burden in order to avoid high pressurization system brought about negative effects.

High turbocharger supercharging system allows the engine to be absorbed by the negative pressure into the high-pressure radical changes, the internal engine parts and material demanding precision machining, required for cooling, lubrication system is also engine is more than the general high, short maintenance intervals, complex procedures, short working life, etc. are disadvantages .. high boost values of the turbine engine.

In the case of engine parts to maintain the original form, without additional manufacturing high-priced precision mechanical parts, mechanical supercharging system allows the engine power output to enhance the percentage of 20-40, but not so the burden of system maintenance , so the major automakers in recent years have developed supercharged engine programs, such as: BENZ, Jaugar, AstonMartin .. etc. senior European automakers have adopted a supercharger system to extend the production life of existing engines, and environmental protection to achieve, fuel-efficient, high efficiency targets to significant savings in development costs of new engines.

4, automotive supercharger

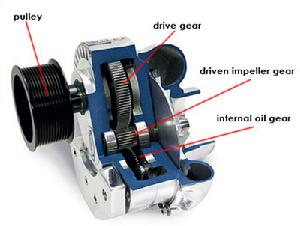

configuration of the supercharger, the supercharger and the engine using a belt pulley connected to the crankshaft using engine speed to drive the supercharger inside the blade, in order to generate pressurized air into the engine intake manifold, the overall structure is quite simple, the working temperature boundary at 70 ℃ -100 ℃, unlike a turbocharger driven by exhaust emissions engine, must touch 400 ℃ -900℃ the high temperature exhaust gas, so the same supercharger system for a cooling system, and the grease in claim NA naturally aspirated engine, maintenance procedures similar parts.

supercharger (SUPERCHARGE) because of the characteristics of the supercharger driven by belt characteristics, thus turbocharger speed and engine speed inside the blade is fully synchronized, the basic features are:

Engine rpmX rpm (R1 / R2) = booster blades of

of the radius R1 of the engine belt disk

the radius R2 of the belt pulley supercharger

due to limitations in manufacturing cost, commercially available engine of the vehicle most of the maximum speed was maintained at 7500rpm or less, preferably in the supercharger should an engine operating region of the 1000rpm-7500rpm, generating a sufficient and stable value of the supercharging, so that the output of the engine 20-40 enhance the percentage, the mechanical supercharger supercharging effect to be generated at low speed, typically from an engine idling region, i.e. can drive the supercharger supercharging effect produced at 1000rpm-1300rpm, and continuing to the engine maximum speed, thus rendering the entire boost curve is a slowly rising smooth curve, via fuel supply adjustment procedures and relief valve, to achieve the target “plateau” of the engine output power curve. The transient response characteristics

5, pressurized application

Because the diesel rely deterioration regulated manner adjust the torque, no throttle valve, the intake air amount per cycle or less, which difference is mainly caused by the mass flow rate of speed variation, the mass flow rate of the diesel engine span of only 6.5: 1 or so. In contrast, conventional gasoline (gasoline means other than direct injection gasoline engine GDI) rely on variable torque adjustment in an adjustable manner, by adjusting the air flow throttle valve, with the? Variable load, the amount of intake air per cycle phase difference large, plus the gasoline engine speed range of variation is much greater than diesel, so the mass flow of gasoline span of up to 75: 1, this indicator is close to 12 times that of diesel. This leads to instantaneous turbocharged gasoline engineWhen the condition is poor. The use of supercharged do not have this problem.

In-cylinder gasoline direct low throttle is fully opened condition, which is almost with Diesel engine; only the high throttle opening conditions will change with the change of the load. Therefore, the mass flow rate of a span with diesel GDI closer, also more suitable for the turbocharger.

supercharger help to reduce emissions gasoline

and the starting gasoline gas mixture after starting the warm-up phase requires special enrichment, resulting in a large amount of hydrocarbon and carbon monoxide emissions. As mentioned earlier, rapidly increasing the temperature of the catalytic converter for gasoline powered cars meet European emission regulations third stage has special significance. The turbocharger exhaust gas temperature decreases, so that the temperature of the catalytic converter is not increased rapidly, which affect the purification efficiency of conversion. If a supercharger, we do not have this problem.

may serve as the supercharger secondary air pump

supercharged Otto engine cost

In order to improve the power-liter gasoline engine, a supercharger may be employed, four valves may be employed. For supercharged 3.8L, two-valve V6 engine with a non pressurized 4.0L V8 four-valve gasoline engine for comparison shows, the supercharged car has good power and torque, and the overall cost than non-pressurized four-valve gasoline engine cars low. This is because the four-valve gasoline engine is more complex, higher costs related tools.

In supercharged Otto engine prospects

Unlike ordinary diesel buses before city diesel buses or trucks, because of its low average speed, substantially little or no the highest speed, plus the long time idling, start, acceleration, deceleration frequent engine operating conditions continually alternating, it is also suitable for a supercharger. Since the performance characteristics of the supercharger and turbocharger are complementary in many ways in recent years in some European countries, luxury cars and high-powered diesel vehicles, these two being installed superchargerTests on the same car.

6, advantages and disadvantages of

supercharged advantages:

turbo technology, completely solve the supercharger response delay with respect to the accelerator, the power output and turbo lag phenomenon of sudden, instantaneous reached throttle response, power output linearly with the speed, the effect can increase drivability. Further, in the low speed high torque, instantaneous acceleration supercharger techniques are superior turbocharging.

supercharger art without lubrication system of the engine is connected with, no cooling, maintenance-free, reliable, and long life. Here are some disadvantages outweigh its supercharged turbo, but they have their own strengths, turbo supercharger ratio also has shortcomings.

inadequate supercharged:

1, the acceleration effect is not very obvious, with the naturally aspirated engine is not very different.

2, will be part of the kinetic energy loss of the engine, a supercharger driven by a belt, or the driving force of the engine in the final analysis.

3, will produce a large number of high speed friction, affecting the speed increase, noise.

4, high maintenance costs.