1. Introduction

2, the composition and the water

1, the composition

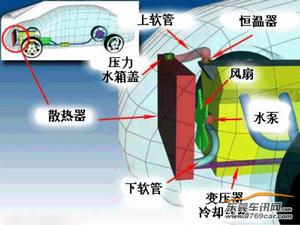

There is currently a large water-cooled system used on automobile engines are forced circulation water cooling system, circulating flow in the cooling system using a pump to force the water. It consists of a heat sink (radiator), the pump (waterpump), the fan (fan), a cooling water jacket (waterjaket) and temperature regulating devices and other components.

2, water

in the radiator cooling water jacket after the water pump pressure to the cylinder block water jacket and the cylinder head through the distribution tube, cooling water in the absorption of a large amount of heat through the cylinder head body water hole back into the radiator. Because of the strong suction fan, a high-speed air flow through the radiator rearward from the front. Thus, the process of cooling the heated water flowing through the radiator core, the heat dissipated constantly into the atmosphere, water cooled heat sink to the bottom, and the pump is withdrawn, the pressure again to the engine water jacket , so the cycle, the heat is supplied continuously to the atmosphere, keep the engine is cooled.

3, the main member

Function: increase the cooling area, accelerated cooling water. After cooling water radiator, which reduces the temperature of 10 ~ 15 ℃, in order to quickly heat sink outgoing heat away, behind the radiator and the radiator fan is equipped with the work.

Structure: radiator tank is also known from the reservoir chamber, the reservoir chamber and a lower radiator core and other components. Top

plus radiator Sheung reservoir outlet chamber, whereby cooling water injected into the cooling system and the whole is covered with a radiator cover. In the storage chamber and the storage chamber are respectively provided with inlet and outlet, inlet and outlet respectively connected with a rubber hose inlet and outlet pipe and the cylinder head of the pump, so that not only easy to install, but when It will not leak when a small amount of displacement between the engine and the radiator. Usually with cushion below the radiator, the radiator to prevent damage to vibration. There drain switch in the outlet pipe of the radiator water storage chamber, the cooling water in the radiator can be let go, if necessary.

a number of cooling water from the radiator core fins and composition, as for the radiator core should have a large heat dissipating area, the heat sink is employed to increase the cooling area of the radiator core. It is configured to form multiple radiator core, commonly used with tube sheet and tube two.

1) most of the cross section of the core segment radiator cooling pipe flat circular shape, which communicates the upper and lower reservoir chamber, a cooling water passage. And a cooling tube of circular section, compared not only heat dissipation area, and the cooling water freezes in the case of expansion of the tube, by means of its flat cross section tube may avoid cracking and deformation. Heat sinks can not only increase the heat dissipation area, further increasing the rigidity and strength of the heat sink. This radiator core strength and stiffness are good, high pressure, but the manufacturing process more complicated and costly.

2) with a tube condenser and radiator cooling core using longitudinally spaced manner along the strip, the cooling apertures to bring the damaged air flow boundary layer of the cooling belt to form the heat dissipation capacity. This radiator core cooling capability, the manufacturing process is simple, low cost, but not as the structural rigidity of the large tube-fin type, and more generally for car engines employed, in recent years, some are beginning to use medium-sized vehicles.

radiator is required, it must have enough cooling area, and all the material better thermal conductivity, and therefore, the heat sink is generally copper or aluminum.

2, the fan (Fan)

Function: increasing the air flow rate through the radiator core to increase the cooling effect, the accelerationWater cooling. Fan is typically arranged behind the radiator, and coaxially with the water pump. When the fan rotates, air suction, so as to flow axially. By the air stream before the core back through the radiator, the cooling water flowing through the radiator core accelerated cooling.

3, water pump (Waterpump)

Function: pressurized cooling water, accelerated cooling water circulation, to ensure reliable cooling. Vehicle engine with the use of centrifugal pump, centrifugal pump with a simple structure, small size, large displacement, and easy maintenance.

The centrifugal pump by the pump impeller and pump shaft composition, or vanes generally radially bent back, the number of sheets is generally 6-9.

When the rotation of the impeller, the pump impeller is driven in rotation together with the water, the centrifugal force, the water being left edge of the impeller, and then to the engine water jacket into the impeller casing through the tangential outlet pipe pressure. At the same time, the pressure reduction at the center of the impeller, the radiator through the water inlet tube will be sucked into the impeller center section. Continuous action thus, constantly circulating the cooling water in the water channel. If the pump is stopped for any reason, the cooling water is still flowing from between the impeller vanes, a heat cycle, as not quickly overheat.

4, the cooling intensity adjusting means

intensity of the cooling means is adjustable according to different engine operating conditions, and different conditions, changing the cooling capacity of the cooling system, i.e., to change the cooling intensity, in order to ensure the engine is often the most favorable temperature state jobs. There are usually two cooling intensity change regulation mode, one is to change the air flow through the radiator; the other is to change the circulation rate and scope of circulating coolant.

Generally the air flow rate change is achieved by using the radiator shutters (fanblind) and various automatic fan clutch (fanclutch).

the air flow regulating louver is frozen in winter and preventing the tank, the use of manual adjustment, there is also an automatic adjustment device.

The fan clutch mechanism is disposed in the fan drive clutch mechanism, according to the automatic temperature control fan speed of the engine, adjusting the amount of fan air flow to achieve the change through the radiator, it can not only reduce the power loss of the engine, saving fuel, but also to improve the life of the engine, reducing engine noise. Common fan clutch in the form of silicone oil fan clutch, a mechanical fan clutch, an electromagnetic clutch and a hydraulic fanForce coupling and so on. Silicone fan clutch applications widely. Function

4, function

of the cooling system is to remove heat generated by the combustion engine because the engine is maintained at the normal operating temperature range. In accordance with the engine cooling it can be divided into water-cooled engine and air-cooled engines, air-cooled engine is driven by the engine fan airstream to cool the engine and the vehicle is traveling; water-cooled engine is cooled by circulating cooling water in the engine engine. Whatever form taken cooling, a cooling system must ensure normal engine not running from overheating in every environment. May by circulating coolant, the excess heat out of the engine, to prevent overheating of the system. In the water-cooled engine, comprising a water jacket, pumps, tanks and thermostat. In the mechanical and electrical equipment industry, the cooling system is an extremely important part, related to the safe operation and service life of the cooling of the electromechanical device, it is easily overlooked in the weak link, such as in high-power electronics cooling system is very the necessary equipment may be by means of circulating coolant, the excess heat out of the engine, to prevent overheating of the system. In the water-cooled engine, comprising a water jacket, pumps, tanks and thermostat.

When the combustible gas in a cylinder mixer combustion temperatures up to 2073-2273K. Parts (e.g., the cylinder block, cylinder head, pistons, valves, etc.) in direct contact with the hot gas if not cooled promptly, wherein the moving parts damage due to normal thermal expansion gap, or that the lubricant fails stuck at a high temperature: high temperature parts due to their reduced mechanical strength or even cause damage Therefore, to ensure the normal operation of the engine, must work at a high temperature the parts to be cooled to cool the engine must be moderate. If the engine cooling is insufficient, inadequate and would appear abnormal combustion phenomena such as exploding and then early cylinder charge, engine power will decrease, and engine parts also due to poor lubrication accelerated wear. However, if excessive cooling, on the one hand due to the excessive heat loss, heat is converted into useful work is reduced, on the other hand since contact with the cold cylinder wall mixed exhalation, so Central vaporized fuel stream and condense and to the crankcase, not only increases fuel consumption, and the thinning effects of lubrication oil, the engine will also resultPower down, increased wear. Accordingly, cooling system task is to work to obtain an appropriate cooling of the engine, so as to maintain the optimum working temperature range.

Part of the heat of the engine temperature directly manipulation scattered into the atmosphere for cooling a series of air-based device is called; first range means that heat transmitted to water supply, and then scattered into the atmosphere is called a water-cooled system is currently widely used in the automobile engine is cooled using water cooling system when the system, because of the cylinder. cover coolant temperature between 353-363K (80-90 ℃);