1, the drag coefficient

drag coefficient: air resistance is the largest and most important external forces encountered when the vehicle is traveling. Air resistance coefficient, known as the drag coefficient is a significant coefficient calculation automobile air resistance. It is a mathematical parameter determined by wind tunnel tests and glide experiments, it can calculate the air resistance when the car is traveling. Drag coefficient depends on the size of shape of the car. Greater drag coefficient, the greater the air resistance. Hyundai drag coefficient is typically between 0.3-0.5.

When the vehicle is traveling wind resistance from the air resistance, the air resistance in general there are three forms, the first gas stream is generated in the vehicle frontal collision resistance, as a piece of wood against the wind to get the line, the resistance experienced by almost all the impact resistance generated by the airflow. The second is the friction, air and across the body will produce the same friction, however, with the fastest speed of the vehicle can travel in general, the friction is small to negligible. The third is the shape resistance, in general, high-speed driving, the appearance of resistance is the main source of air resistance. Exo vacuum zone created by the resistance from the rear of the vehicle, the greater the vacuum zone, the greater the resistance. In general, good resistance RV of San Xiangshi will be smaller than the hatchback SUV.

The method of calculation of the drag coefficient measured 🙁 wind tunnel experiments)

provided a rigid body in the movement direction of the projected area S, the air density p, the air in front of the rigid body moving with a velocity v thrust F (rigid then the size of the air resistance is F).

The method of wind tunnel tests are:

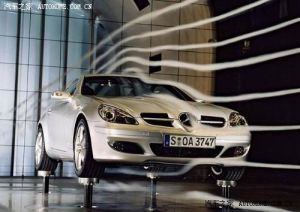

The car was placed on a platform in the tunnel, a huge fan front point, four wheels was stuck on the platform, and each wheels provided at the two force sensor, a vertical direction of the measuring force, the measuring force in the other horizontal direction. Before starting the fan, the sum of the measured force perpendicular to the load cell of four = vehicle weight; four horizontal force sensor readings are 0; when the fan is started, a certain wind speed, the speed for simulating vehicle movement in this case, the sum of the four load levels measured by the sensor corresponding to the drag force; four vertical load force measured by the sensor before starting the fan than the sum hasDecline, decreased corresponding to the lift generated by the vehicle movement. The car’s aerodynamics design is committed to reduce wind resistance, while reducing lift.

When using the air resistance wind tunnel test measured value at a constant speed, we can be calculated according to the value Cd of:

Cd = 2F / (pSv2) (later V2 is the square of the V, which is the square of the velocity, do wrong.)

where, F v, and obtained by the above test, the projected area S of the air density p and the car forward direction also it’s easy.

Finally, it should be noted that a problem: the drag coefficient Cd is a constant at different speeds it? In fact, our previous reasoning process that can not prove that it is a constant. In fact, with the rate of change of the drag coefficient and can not maintain a constant! A long inspection extreme case can be understood: For example, when the moving speed exceeds the speed of sound, will produce a large sound barrier, the resistance suddenly surge, significant deviation is proportional to the parabolic curve v2. This shows that not drag coefficient does not vary with changes in speed. Fortunately, however: Tests show that a certain shape of the car, within a certain speed range (for cars, in the speed range of 50–120km), Cd is almost constant, which allows us to use it to measure a car the aerodynamic design level possible.